The Farm’s pear orchard was planted back in the 1970’s and unlike apples, pears are extremely disease resistant and require no sprays and very little maintenance.

This is good because after the economic change in 1983 the community could not afford to pay someone to maintain the orchards. Now decades later, the pear orchard delivers some of the best tasting fruit you can imagine.

Volunteers occasionally do some pruning and fruit tree fertilizer spikes have been added to a few trees over the years. The annual harvest is modest but consistent, and in some years we are blessed with the occasional bumper crop.

Some trees are more prolific than others and to be honest the orchard could benefit from a little more attention. The harvest window is short, about 2 weeks from when the first windfalls begin falling on the ground until the last pears have achieved ripeness.

About 50% of the crop is infected with a virus that causes the fruits to form dimples and become deformed.

At each dimple their is a scar or tough spot in the flesh, almost like pear “gristle.”

You can use a knife to cut these sections out and salvage the fruit to either side.

The only remedy for the virus is to plant a new orchard.

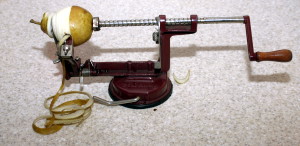

I use a hand cranked apple peeler to remove the skin, core out the center and slice the flesh into rounds perfect for drying.

The peeler works best on fruit that is round and evenly shaped.

The peeler is spring loaded so that it can move in and out following the circumference of the fruit.

The peeler also works best when the flesh of the fruit is firm and not overly ripe.

Soft, juicy pears are truly luscious, but the corer simply spins in the soft flesh and will not push the body of the pear past the peeler or through the slicer.

I find it works best when I process the fruit on the same day that I pick it. Each day you wait the number of fruits that are too soft to send through the peeler increases.

If the fruit is too ripe for the peeler, you still have the option of peeling and slicing by hand, eating fresh or cutting up for canning.

The sliced sections are placed on trays in the dehydrator and it takes about 24 hours until they are finished.

Drying concentrates the sugars and the finished pieces are literally as sweet as candy.

I use an Excalibur Dehydrator which has a temperature controlled thermostat and a fan.

I set the thermostat at 104 degrees, a temperature which does not destroy the enzymes, so that this can be considered a raw food. The 10 trays make about 1 1/2 to 2 quarts of dried pears.

I usually store my pears in an extra refrigerator I have for food storage. Otherwise if you have not truly removed all the moisture or dried the slices sufficiently, at some point the dried fruit could begin to grow mold. Commercially dried fruit often has sulfur dioxide added a a preservative to prevent this.

The fruits that are over ripe or misshapen I cut up into chunks, place in a pot, cook for about 10 minutes and then preserve in canning jars. I usually add a little brown sugar to help the preservation. These taste great in a bowl of oatmeal midwinter.

If I have the time and the motivation, I can also send the cores, peels and any soft fruits through my Champion Juicer. You do not get actual juice, more like pear sauce.

This can be placed on Teflon sheets and dried into pear leather or cooked down on the stove with a little brown sugar and cinnamon to make pear butter. It’s delicious!